Technology

The Next Generation Oxidation Technology

Liquid Ozone has advanced the chemistry of disinfection and oxidation through the effective use of “reactive oxygen species” (ROS) . When added to water, various ROS are formed, including superoxide (O₂- ), hydroxyl (OH- ), singlet oxygen (1O₂), hydroperoxyl (HO₂- ) and peroxide

(O₂2- ) and it is these ROS that provide the disinfecting strength of Liquid Ozone.

Liquid Ozone advances oxidation disinfection technology by translating what traditional gaseous ozone does - creating ROS - into simple to use liquid formulations. The result is a disinfection ability, for the management of viruses, bacteria, molds, and biofilm that is more than twelve times that of conventional chlorine treatments; it far exceeds peroxides and it provides a residual protection which gaseous ozone cannot provide.

What is Oxidation?

An oxidizing agent is something that takes electrons from another substance, and it is this taking of electrons by ROS that provides disinfection.

How Oxidation Works

In the treatment of organic material like bacteria and viruses, the organics are overwhelmed by ROS, causing oxidation (loss of electrons) on many levels, ultimately leading to cell death. This ROS function is very different from that usually found in the use of such products like chlorine in that it does not poison, it actually destroys the target. The target cannot become immune to this free radical action.

Iron, manganese and sulfer dissolved in water are oxidized to form insoluble metal oxides or elemental sulfer; these insoluble particles can then be removed by filtration.

ORP

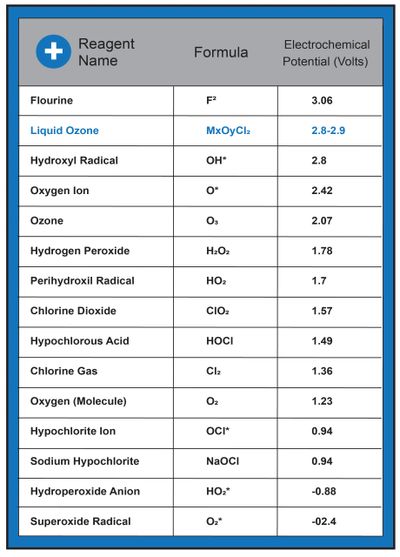

Oxidation reduction potential (ORP) measured in millivolts (mV) is a measure of the ability to take electrons; the strength of the millivoltage is directly proportional to the oxidative disinfection strength. Because substances with positive ORP reading are looking to acquire electrons, they are considered oxidizing agents. The unique chemical makeup of Liquid Ozone places it as the reagent with the highest electrochemical potential, second only to flourine.

Using Liquid Ozone versus conventional disinfectants enables the use of ORP (oxidation-reduction potential) as an objective measure to ensure desired treatment levels, which can help achieve the desired disinfection level with less product. Because of the effectiveness of Liquid Ozone, its residuals fall well below Federal Drug Administration’s (FDA) Maximum Contaminant Level (MCL). ORP has been used as a bench mark to measure disinfection energy in water treatment systems.

In comparative lab tests, Liquid Ozone Plus out-performed:

- Peroxide

- HDH Peroxy

- Sani-T-10

- Ethyl Alcohol

- Glutaraldehyde

- Peroxide + Sani-T-10

- Sodium Hypochlorite

- Chlorine Dioxide

- Isopropyl Alcohol

- Formaldehyde

- Peracetic Acid

- Chemchlor

- Acidize DS-50

- Calcium Hypochlorite

- Storox

- ProOxine

- Dowicide -1

- Jet Oxide

Copyright © 2010 Ag Fluid Products - All Rights Reserved.

AFP CAN / AFP USA / AFP INT